Source Spotlight: Kelvin Cooperage

Among the most significant decisions a distillery can make is who they partner with for their barrels. There are a lot of facets that impact the flavor of a spirit, such as what grains, malts or sugars are used, how the spirit is distilled, and how long it is aged. The barrel, however, can make or break the flavor of a spirit. It is a crucial aspect in the finished product that a consumer enjoys.

At Mad River Distillers, while we’ve experimented with a variety of different barrels over the years, our go-to source for barrels is Kelvin Cooperage. A craft cooperage based out of Louisville, Kentucky, Kelvin Cooperage has more than 58 years experience producing and repairing barrels.

“Since we began aging spirits almost 10 years ago, we have experimented with a variety of different barrels produced by cooperages across the country. Once we got our hands on some Kelvin barrels, it didn't take long for us to realize that their barrels were yielding consistently good whiskey and rum. Couple that with their competitive pricing and friendly staff, and we realized Kelvin Cooperage was a good match for us.”

Alex Hilton, General Manager & Head Distiller at Mad River Distillers

The company’s origin began in 1963, when the family-run and operated business was founded by Ed McLaughlin in Scotland. At the time, they purchased once-used Bourbon barrels from Kentucky to ship around the world. In 1992, they expanded by opening what is now a single, successful location in Louisville, Kentucky. Today, son Paul McLaughlin runs the company, continuing to purchase once-used Bourbon barrels from Kentucky (in addition to building new barrels), which are repaired as needed and loaded on shipping containers to be sent around the world—primarily to Scotland and Ireland.

The benefit of a once-used barrel is that it is less expensive to purchase, and because it has already been seasoned, used barrels are ready to use. With countless distilleries along the Bourbon Trail, and across the United States, this opened up a large inventory of once-used barrels for the rest of the world. However, in order to make and sell an “American Whiskey” in the United States, it must be aged in new (not used) oak barrels.

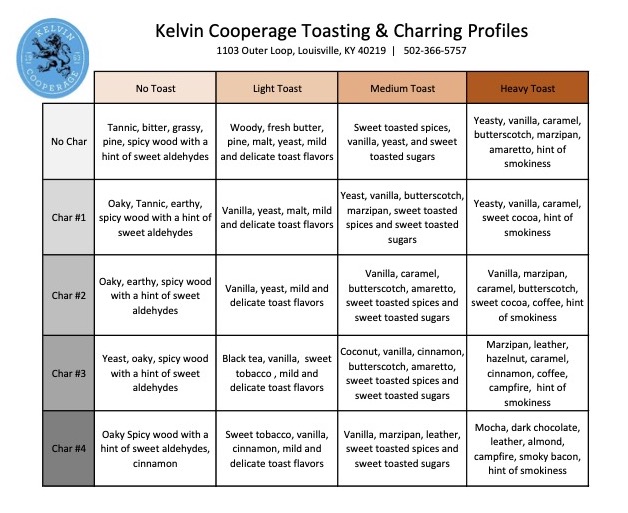

At first producing new wine barrels, the company decided to begin producing new bourbon barrels just as the craft bourbon industry began to boom. Because wine barrels are toasted only, Kelvin Cooperage saw the specific benefits of toasting barrels, and so the business expanded to offer new barrels with both a toasted and a charred wood profile.

Kelvin Cooperage offers new 15, 25 and 53 gallon barrels, which they toast and char over natural oak fires. This is a main point of differentiation for the cooperage. While most cooperages use propane on a timer to char their barrels as they lay on their bilge or belly (side), at Kelvin Cooperage, production scraps are used as fuel to toast and char the barrels as they sit upright. A 15-20 minute toast is first done on all new bourbon barrels before the charring occurs, and only 9 barrels are processed at a time. This traditional method of coopering takes more time as the toasting is done by sight and smell, rather than along a conveyor belt. So while not as many barrels can be produced this way, more time is spent to deliver the requested level of toast and char to each barrel, making these craft barrels more superior.

“Proper toasting penetrates through the full thickness of the stave, caramelizing and activating the sugars in the wood. The charring process only affects the first few millimeters of the wood and will not burn off the toasting that has penetrated deep into the staves. Char level serves two primary purposes: first is to add color, so the heavier the char the quicker the spirit will pick up color; the second is for the carbon filtration effect, which helps mellow and round out the spirit. A heavier char will add more smoky notes to the whiskey.”

Britney Wimsatt, Director of Craft Sales & Marketing at Kelvin Cooperage

Once a spirit is in a barrel, maturation begins. During warmer weather, the spirit swells and soaks into the wood barrel. As it does, it picks up on both color and flavor from the toast and char. During colder weather, the spirit shrinks back through the wood, picking up on more color and flavors. This swelling and shrinking of the spirit as temperatures fluctuate over time, is a crucial aspect in the finished spirit.

How much toast and char is in the barrel as the spirit swells and shrinks during maturation, impacts the amount of flavor imparted. When a barrel is purchased, a level of toast and char can be specified—each level imparts different flavors on the finished spirit. According to Britney Wimsatt, the Director of Craft Sales & Marketing at Kelvin Cooperage, most distilleries opt for a medium toast and number 3 char. That level can impart flavors of coconut, vanilla, cinnamon, butterscotch, amaretto, sweet toasted spices and sweet toasted sugars. A heavy toast and a number 1 char can impart other flavors, such as vanilla, caramel, sweet cocoa and a hint of smokiness. This is, in large part, where different Bourbon and Whiskey brands create their unique flavor profiles.

Using properly made barrels that retain the spirit, choosing a toast and char that imparts the desired flavor profiles, and storing the barrels in a location that benefits from temperature shifts over time… these are all critical to the finished product. At Mad River Distillers, we’ve found great success in sourcing our craft barrels through Kelvin Cooperage, and in the unique flavors they help impart on our various spirits. As a distillery based in Vermont—a state that enjoys all four seasons—our spirits benefit not only from the quality barrels we use, but from the shifts in temperature that add great flavor to our products and make Mad River Distillers spirits entirely distinctive.

Kelvin Cooperage is part of the White Oak Initiative focused on sustainability of White Oaks for current and future generations. To learn more, visit www.whiteoakinitiative.org.

Written and published by Brianne Lucas on September 27, 2021.